System for Berry Crop Yield Management Farmpro

- Client

- Memoberry

A few years ago, the large Georgian agricultural company Memoberry lamented the lack of a tool for accounting for the harvest of berry crops (in this case, blueberries). The only solution in the country, developed at the request of an NGO overseeing this agricultural sector, turned out to be so inconvenient that its use brought more drawbacks than benefits. Foreign solutions appeared cumbersome and, although they could generally be successfully adapted, they did not solve some of the tasks that would have been highly desirable to address.

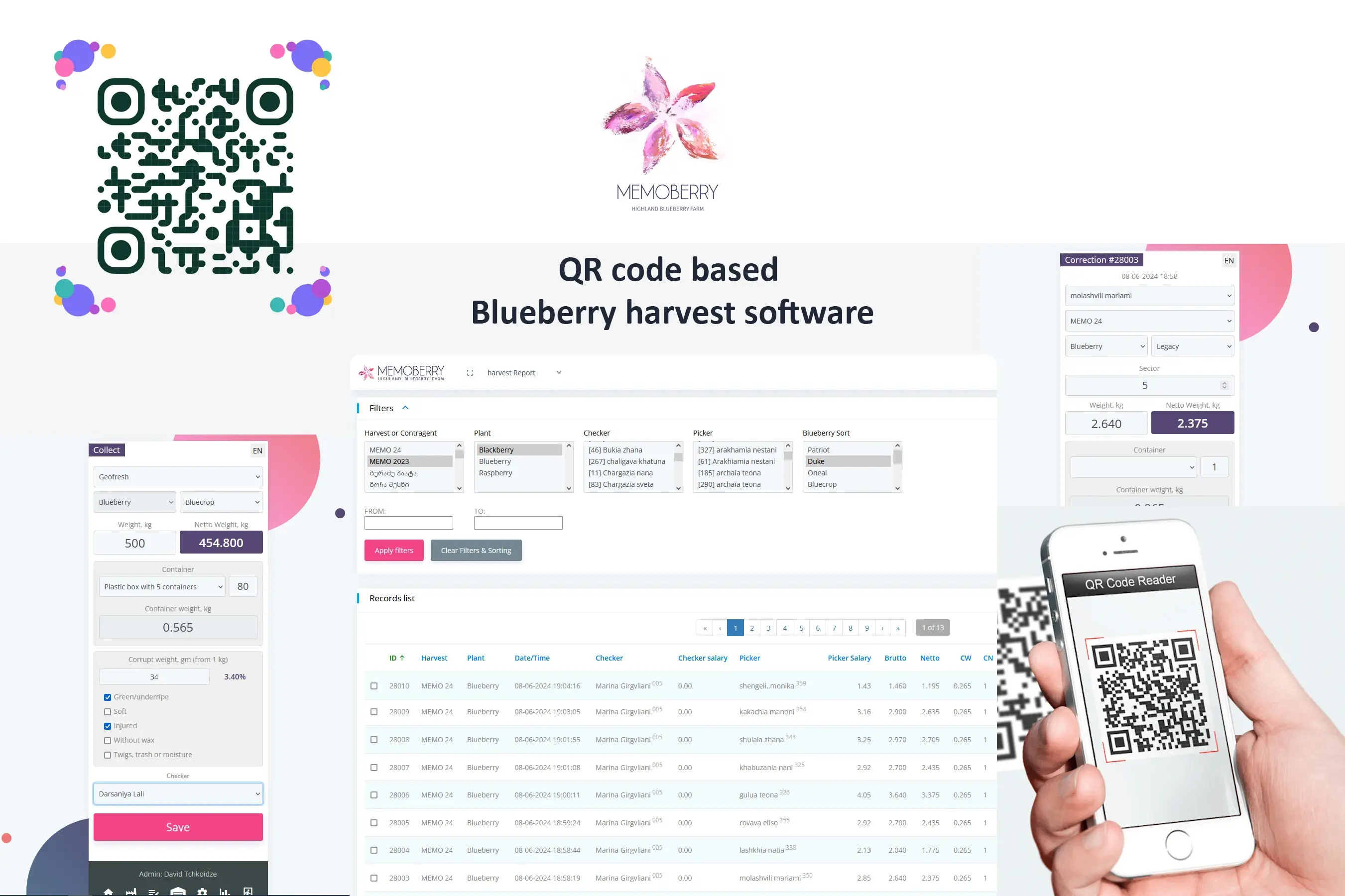

In a short time, we developed a simple and effective system that not only automated the harvest accounting process but also tracked product purchases from small farms, and payroll accounting. Additionally, thanks to unique codes, our system allows you to track each berry package: where it was collected, when, what variety, in which sector, and identify the picker and receiver.

The system is based on QR codes.

The system allows printing labels with QR codes on a thermal printer (a Brother thermal printer was chosen). Each QR code is unique, so the product can be tracked, and most importantly, it cannot be processed twice (either by mistake or intentionally).

The process proceeds as follows:

Before heading out to collect, each picker receives a roll or pack of labels with QR codes. QR codes are affixed to the collection container directly at the receiver's table. The receiver (already registered and authorized in the web application) weighs the berry package and scans the QR code. The application prompts to fill out a form where the picker's data is already indicated (QR codes are personalized). The picker only needs to specify the gross product weight and select the container, accordingly calculating the net product weight.

A common case in the agricultural sector is the purchase of products from small farms, which, due to small volumes, cannot organize sales independently. In this case, the same QR code scheme is used.

The operations for product acceptance are saved in the database, and piecework wages are calculated based on the net weight for the picker and receiver. The system also allows for accounting for various types of containers, plantation sectors, berry varieties, and more.

Using unique QR codes prevents any duplication of records.

Each unit of warehouse product has its unique identifier in the form of a QR code, by scanning which you can get complete information about it: net and gross weight, container weight, variety, sector, receiver and picker data, collection/submission date, and time.

Perhaps one of the most important advantages of our system is that acceptance can be performed by a person without any qualifications, and moreover, quite far from advanced smartphone use. Receivers work on their own smartphones. Anyone can be assigned as a receiver. Registration/authorization on the site as a receiver (with administrator confirmation) – and you have a receiver. The work will never stop.

Another advantage is mobility. No complex equipment is required, no electricity is needed. Moving the acceptance point to another part of the plantation is very quick.

At any time, the desktop reporting system is available with:

- Harvest reports with all possible filters and sorting

- Payroll reports

- Payroll statements

- Payroll issuance accounting and financial report generation

The project is gradually evolving, every year we add and improve functionality. Future plans:

- Currently, the system is implemented as a web application, which is not perfect; the next step will be a mobile application for Android and iOS platforms.

- At the moment, scales are not integrated into the system, there was no such need. In the current version, any, the cheapest scales can be used, which can be disposed of when broken and replaced with new ones. Integrated «smart» scales are significantly more expensive, generally require electricity or a powerful battery, and need to be stocked for quick replacement. And you can't usually buy them in a store. In any case, by the next season (2025), we plan to complete the integration of the system with scales, and the receiver will not need to manually enter the weight.

- We plan to relieve the administrator of the task of preparing QR codes. We plan to use touchscreen devices so that employees can register themselves as pickers and receive QR codes before collection.

- In the current version, the system can export data to Excel, CSV. In addition to this, we plan to create an API that will allow not only remote data retrieval but also customize the output format, fields, and more.

By the summer of 2025, we plan to present a commercial multi-user version of our product and start selling on a subscription basis. We invite investors and interested parties to participate in the project. We are ready to consider equity participation in the project and the transfer of exclusive distribution rights in a particular country/region.

With Farmpro, we forgot about accounting problems. No paper records, no Excel. The program does everything for us: counts the harvest, calculates salaries, provides reports, and allows us to control the harvesting process. We are particularly pleased that there is no training process needed – just show it once, and the receiver is ready to work. No special equipment is required, everyone works on their own smartphone. And excellent support – every season, something new and useful appears in the program.

Memoberry

Dato Nodia , Manager